One of the fastest and most precise ways to create plastic parts that are both small and large is through the plastic injection molding process. Using precision manufactured molds, specific amounts of melted plastics under pressure are shot into molds that cool rapidly and release the parts without any need for subsequent finishing processes.

While there are a number of different plastic injection molding companies in most major industrial and manufacturing centers across the country, they are not all the same. When considering the right contract manufacturing company to partner with for your plastic injection molding needs, there are several factors to review before choosing the best service.

Production Capacity

Comparing plastic injection molding companies is not just about the volume of production, but also about the turnaround time for orders. Often small companies have limited ability to complete large orders, or they may have the ability but only with extended turnaround times.

For most OEMs, the capacity also includes the ability to scale up production to meet demand. To evaluate this factor, anticipating what your maximum production capacity is projected to be in the future is essential when discussing the job.

Ability to Work With the Material

Not all plastic injection molding companies have experience in working with all types of materials and resins. Knowing what you need and the types of resins required for the parts and components helps the OEM to choose a service provider with experience and expertise.

Most of the top injection molding companies are able to source the material for their customers, but they may also be willing to work with material supplied by their customers. This is an important factor to verify if the OEM uses anything other than standard grade and types of resins.

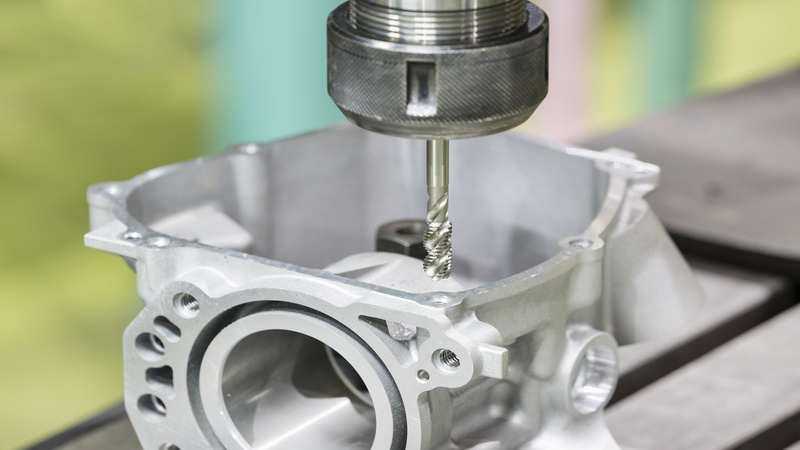

Finally, check to make sure the company offers the additional services required. This can include engineering and design of the molds as well as tooling of the molds and assembly of completed parts.