Aluminum extrusions have become essential components in a wide range of industries due to their durability, lightweight nature, and versatility in a variety of applications. Ready-made extrusions allow businesses and manufacturers to rapidly access standard profiles that are ready for immediate use, resulting in increased production efficiency and flexibility. These extrusions, whether used in construction, automotive, or consumer products manufacture, provide a practical and cost-effective alternative for tasks that require both quality and precision.

The Value of Aluminum Extrusions in Manufacturing

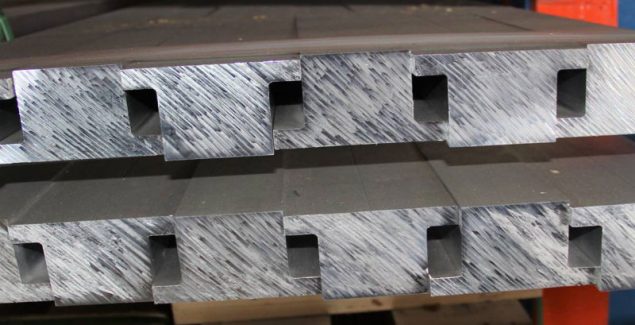

Aluminum is well-known for its strength, corrosion resistance, and lightweight qualities, making it a popular choice for industries that require materials that are reliable and long-lasting. Aluminum extrusions are made by pressing metal through a die and shaping it into particular cross-sectional profiles. These profiles vary greatly, ranging from simple square or rectangular tubes to sophisticated geometries with many channels or bespoke patterns. Aluminum retains its strength through the extrusion method, which also makes it easy to machine, cut, and connect. These extrusions work as building blocks, expediting the manufacturing process by shortening lead times and lowering costs related to bespoke designs. This advantage is especially useful in areas such as transportation and construction, where materials must meet exacting standards for safety and efficiency.

Advantages of Stock Aluminum Extrusions for Various Applications

Stock aluminum extrusions have various features that make them an appealing choice for many sectors. One of the main advantages is availability. With stock alternatives, firms can get materials without having to wait for custom production, which is important in industries with tight deadlines. Construction and infrastructure organizations, for instance, use stock extrusions to prevent delays in building and restoration projects. Furthermore, the large range of shapes and sizes available enables businesses to select extrusions that are tailored to their requirements, allowing them to begin production immediately and avoid design bottlenecks. Many organizations, particularly those involved in high-volume production, benefit from the cost reductions that stock options offer. This recyclability is a significant advantage for industries that prioritize environmental sustainability while maintaining high-quality standards.

Practical Applications and Future Trends

Stock aluminum extrusions are commonly utilized in the building of frames, enclosures, and supports due to their versatility. In commercial and residential construction, these extrusions provide structural support for windows, doors, and curtain walls, demonstrating strength without adding excessive weight. Other industries, like renewable energy, utilize extrusions to fabricate lightweight frames for solar panels and wind turbines. Aluminum extrusions’ adaptability also makes them suitable for new technology and innovative product designs. In recent years, industries have shifted toward lightweight, resilient materials to fulfill changing customer needs and regulatory regulations. This advancement will significantly cut lead times, making aluminum extrusions a more viable option for a wide range of demanding applications. Their durability, cost-effectiveness, and environmental benefits make them viable options in a variety of industries.