Zinc nickel plating is made up of an alloy of zinc and nickel. This creates a unique finished product that has all the corrosive resistant properties of zinc but also is very durable with the addition of nickel. This alloy has a lot of applications in a variety of fields, including automotive and industrial, with possibly even more applications in the future as it may serve as a replacement for cadmium. The quality zinc nickel plating process is an interesting one that results in high-quality protection at an affordable price.

A Brief Run-through of the Zinc Nickel Plating Process

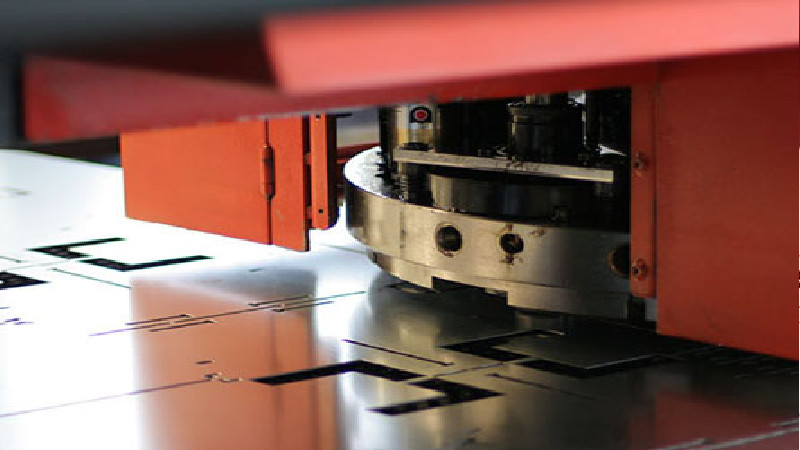

The method for applying zinc nickel alloy deposit to metal involves an electroplating process. First, an electrical current is used in order to apply the zinc-nickel alloy onto the surface of whatever part it is meant to cover. An additional sealant can be applied in order to increase corrosion resistance if so desired. Even without this additional sealant, however, the unique qualities of zinc nickel plating provide exceptional protection against corrosion, as well as heat resistance.

Additional Information

As a true alloy, zinc-nickel is the ideal choice for steel substrates and makes a good base for applications with bondable rubber. It is also very receptive to both primer and adhesive. This alloy provides even coverage over the entire surface, with an even amount of nickel distributed throughout. It will be blister free and resist showing whiskers and burn marks even after enduring stress and high heat.